Our team expertly crafts panels, tailoring them to specific site conditions and ensuring durability against environmental factors. With our engineers’ structural design prowess, each panel is built to withstand various loads, ensuring safety and strength.

Utilizing Building Information Modeling (BIM), we pre-emptively address any design challenges, ensuring seamless construction. Our thorough pre-fabrication process includes rigorous approvals and in-house material procurement for quality assurance and timely progress.

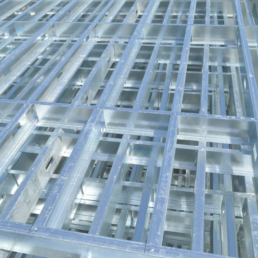

In fabrication, our meticulous approach guarantees perfection in every panel. We rigorously check connections and patterns, collaborating closely with contractors for optimal panel sequencing and efficient job-site delivery.

Our efficient installation process speeds up construction. Panels delivered in precise installation order reduce on-site labor, improve safety, and streamline overall project flow.

Prefabrication Systems

Load-Bearing

Our load-bearing system lets you harness the strength of light gauge steel. Exterior and interior wall panels create the structure of the building and take on the load capacity from the foundation up.

Bypass

Our bypass framing system provides one of the quickest ways to close in a building. The exterior steel stud runs past the structural steel or concrete structure. These wall panels can span multiple stories and can be used on any size building.

Custom Prefab

Fastwalls is not limited to the prefabrication of walls. We can fabricate other CFS elements such as roof trusses, floor joists, and architectural elements to meet design requirements.

Soffits & Bulkheads

Fastwalls has created and delivered a superior alternative to onsite soffit framing. The most complex architectural and detailed framing work can be prefabricated and delivered in sections ready to be installed.